How to manufacture a filter that too quite easily. Making the filter begins with a layer of sand, fibers, activated charcoal, sand, and stone. The result ... SERR ... water was turbid, yellow or even black plus the smell though will be clear and without odor after passing through the filter. With this simple screening method, water is initially unfit for our consumption can now be used again in everyday life.

Material :

- 3 pieces of container can be barrels, drums, buckets or cans connection / plastic bottle that serves as a container precipitation, filtration container, and the container of clean water.

- River stone

- ijuk

- Fine sand

- Coconut shell charcoal

- zeolite stone

- Gravel

- Small stones

- Creating Simple Water Filter

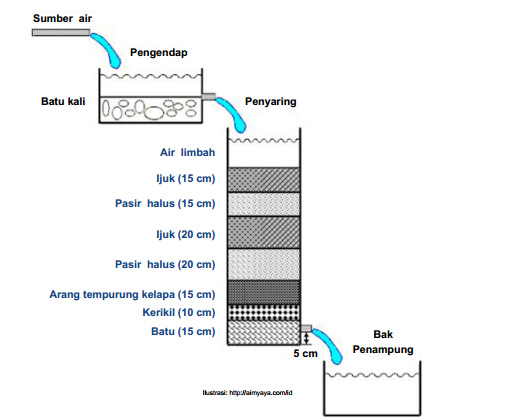

- Prepare a first container which serves to precipitate impurities in the water. So that the deposition process runs perfectly, at the bottom of the container we put stones times.

- Under the first container, then build a second container which serves to filter the water that comes out of the container deposition.

- In a second container (filtering), we enter the composition of the material that we have prepared in advance. if sorted from the bottom, a layer that consists of a layer of small stones as thick as 15 cm, gravel layer 10 cm thick, layer coconut shell charcoal as thick as 15 cm (for charcoal we can add its thickness to further reduce odors or can also add a single layer of stone zeolite in it jka problems we face quite heavy), fine sand layer 20 cm thick, thick layer of longer fibers 20 cm, 15 cm thick fine sand, and lastly as the uppermost layer is a layer of fibers back as thick as 15 cm. Of the top layer of the container deposition of this water we put into it.

- The water that came out of the container bottom layer filtering ago we channeled into a third container that serves as clean water tanks are already completed screened. The reservoir container position directly beneath the filtering container.

No comments:

Post a Comment